Mobile Crusher Plants & Machine

JXSC provides mobile/portable crusher machines for Stone, Rock, Cobble, Granite, Basalt, Iron Ore, Limestone, Quartz, etc.,

JXSC provides mobile/portable crusher machines for Stone, Rock, Cobble, Granite, Basalt, Iron Ore, Limestone, Quartz, etc.,

Feeding size: <800mm

Capacity: 20-300T/H

Applications: It is widely used in mineral processing, coal, building materials, the chemical industry, refractory, metallurgy, cement, glass, ceramics, power, and other industries.

JXSC is a brand mobile crusher manufacturer in China. It helps set up mobile crusher stations for your different plants. It supplies mobile crusher machines such as jaw crushers, impact crushers, hammer crushers, cone crushers, and portable VSI sand-making machines. All mobile crushers are customized and best-selling. The small mini mobile crusher is especially popular!

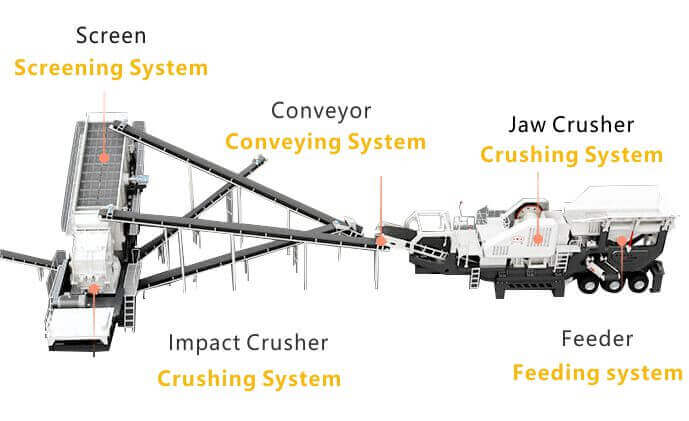

Mobile crushers are divided into tire-type mobile crushing stations and crawler-type mobile crushing stations according to the walking mode. Diverse unit configurations can be performed according to the user’s production requirements. The main matching hosts are jaw crusher, Impact Crusher, cone crusher, heavy hammer crusher, and sand making machine.

Mobile crushing stations are flexible and convenient. They have strong mobility, which can save a lot of infrastructure and relocation costs. They can break the material on site and move with the advance of the raw material mining surface, greatly reducing the transportation cost of the materials. Based on the original technology, the optimized combination has launched a new mobile crushing and screening equipment, which can fully adapt to the various situations of mobile crushing screening, create more business opportunities, and lower production costs for customers.

In the operation process of the integrated small mobile crusher, the material is evenly transported to the crusher through the feeder. When the material enters the action area of the plate hammer, it is broken by the high-speed impact of the plate hammer, then thrown to the impact device installed above the rotor to be broken again, and then rebound from the impact pad to the action area of the plate hammer to be broken again.

This process is repeated until the material is crushed to the required size and discharged from the lower part of the machine. By adjusting the gap between the reaction frame and the rotor frame, the particle size and shape of the material can be changed. The spring device is used behind the machine’s induction plate. When the uncracked materials enter the crushing chamber, the front and rear reaction frames move backward, and the uncracked materials are discharged from the machine.

The small mobile crusher is an efficient and convenient ore-crushing processing equipment that can be processed from ore during processing and production. It can also be moved in the use process, making it more convenient. Small mobile crusher has the characteristics of reasonable matching of crushing equipment at all levels, smooth discharge of the whole line, convenient operation, reliable operation, high efficiency, and energy saving. In particular, it has good mobility, can be extended with raw materials or construction sites, and can be combined to meet the needs of different materials.

A Mobile Crusher line can also be called a mobile crushing station, mobile crushing machine, mobile crusher plant, etc. Its main characteristics are that it can be mobile operation, walk freely, transfer more conveniently, ensure the safety of equipment production at the same time, and work more reliable.

A complete mobile crushing production line, classic with mobile jaw crusher + mobile impact crusher, double machine collocation, realize the rough crushing, fine crushing operation of stone, construction waste, etc. It only takes a few days to build the whole production line without piling, which is nearly a month faster than the fixed crushing production line.

Mobile Jaw Crusher Plant Technical Parameters

| Model | PE-400*600 | PE-500*750 | PE-600*900 | PE-750*1060 |

| Main Motor and Diesel Power (optional) | 30KW-6 | 45KW-6 | 75KW-6 | 110KW-6 |

| Vibrating Feeder Motor | 3 kW | 3 kW | 11 kW | 15 kW |

| Conveyor Belt Motor | 4 kW | 4 kW | 5.5 kW | 7.5 kW |

| Capacity | 20-40 T | 30-80 T | 80-200 T | 120-300 T |

| Maximum Feed Size | Within 40 cm | Within 50 cm | 60 cm | 75 cm |

| Belt Size | 6000*600 mm | 6500*600 mm | 8000*800 mm | 90000*1000 mm |

| Overall Dimensions | 8000*1000*2300 mm | 9000*1200*2400 mm | 12000*3000*3100 mm | 12000*3060*3900 mm |

Mobile Hammer Crusher Plant Technical Parameters

| Model | Feed Size | Discharge Particle Size | Capacity(m3/h) | Number of Motor Poles (kW) | Weight(T) | |

| 400*300 | ≦200 | ≦25 | 5-10 | 4 | 7.5 | 0.8 |

| 600*400 | ≦250 | ≦30 | 10-22 | 4 | 11 | 1.5 |

| 800*600 | ≦250 | ≦30 | 18-40 | 4 | 22 | 3.2 |

| 1000*800 | ≦350 | ≦35 | 25-50 | 4 | 55 | 4.3 |

| 1000*1000 | ≦300 | ≦35 | 30-55 | 6 | 110 | 8 |

| 1250*1250 | ≦350 | ≦35 | 35-65 | 6 | 180 | 14 |

| 1400*1400 | ≦350 | ≦35 | 50-100 | 6 | 280 | 32 |

| 1600*1600 | ≦350 | ≦35 | 100-150 | 8 | 480 | 37.5 |

Mobile Impact Crusher Plant Technical Parameters

| Model | Capacity(T/H) | Inlet Size L*W (MM) | Feed Size(MM) | Discharge Particle Size(MM) | Equipped Power(KW) | Diesel Engine Power(KW) |

| GZ80 | 50-60 T | 600X250 | ≤180 | ≤5 | 60 | 150 |

| GZ100 | 70-80 T | 800X330 | ≤180 | ≤5 | 90 | 260 |

| GZ150 | 90-100 T | 1000X350 | ≤195 | ≤5 | 132 | 285 |

| GZ200 | 100-120T | 1200X450 | ≤200 | ≤5 | 160 | 330 |

| GZ250 | 130-150T | 1200X600 | ≤250 | ≤5 | 220 | 400 |

| GZ300 | 150-180T | 1600X600 | ≤300 | ≤5 | 315 | Diesel Engine Set |

| Note | 1. The mobile high-efficiency impact crusher can be powered by either a power supply diesel engine or dual power.

2. The adjustable width range of the discharge seam is 5-20 mm; Finished sand can be controlled within 3mm. 3. The frequency conversion electric cabinet is used to adjust the number of revolutions and control the particle size of the discharging material. |

|||||

Power Plans of Mobile Crushing Sand Machine

| Model | Scheme 1 | Scheme 2 | |

| Auxiliary Power | HD80 | Main power motor of crusher: 75KW

Feeder motor:7.5kw Discharge motor: 5.5kw |

Diesel Power

Power: 155 kw Auxiliary motor of sorting screen: vibration motor 15kw Main belt motor: 5.5kw Finished product conveyor: 8m*600mm (4.0kw) 5 sets |

| HD100 | Main power motor of crusher: 110KW

Feeder motor: 7.5kw Discharge motor: 5.5kw |

6126 Diesel Power

Auxiliary motor of sorting screen: vibration motor 15kw Main belt motor: 5.5kw Finished product conveyor: 8m*600mm (4.0kw) 5 sets |

|

| HD150 | Production capacity per hour(T / h): 100-130 tons

Total weight tons (T): 16 tons Equipment dimension length x width x height (m): 10x3x3.5 Dimension of main box mm: 3830x1855x600 Maximum feed size mm: ≤ 550 motor power kw: 160 Diesel engine model: 615 |

||

| HD200 | Main power motor of crusher: 200KW

Feeder motor: 7.5kw Discharge motor: 5.5kw |

618 Diesel Power

Auxiliary motor of sorting screen: vibration motor 15kw Main belt motor: 5.5kw Finished product conveyor: 8m*600mm (4.0kw) 5 sets |

|

| HD250 | Main power motor of crusher: 260KW

Feeder motor: 15kw Discharge motor: 7.5kw |

Large 500 diesel generator set is adopted

Input bandwidth 12000mm Required size of raw materials: ≤ 100 |

|

Mobile Sand-Making Machine Technical Parameters

| Model | Capacity(T/H) | Dimensions(L*W*G)(M) | Bin Size | Maximum Feed Size | Motor Power | Diesel Engine Model |

| HD80 | 50-60 | 10x3x3.2 | 3620X1640X550 | ≤350 | 75 | 6108 |

| HD100 | 70-90 | 10×3.3×3.4 | 3830X1800X600 | ≤400 | 110 | 6110 |

| HD150 | 100-120 | 10x3x3.5 | 3830X1855X600 | ≤550 | 160 | 615 |

| HD200 | 150-180 | 11x3x3.5 | 3830X1995X600 | ≤600 | 200 | 618 |

| HD250 | 200-250 | 13.6×3.0×4.3 | 4350X1995X600 | ≤800 | 260 | Diesel engine set |

| HD300 | 280-300 | 14×3.5×4.5 | 4350X2200X600 | ≤800 | 315 | Diesel engine set |

| Note | 1. Aperture of sand making sieve plate: 5mm, 8mm, 10mm, 12mm, 15mm;

2. The aperture of stone sieve plate: 30mm. 40mm, 50mm, 60mm. 80mm; 3. The hammer head is made of high-strength steel or high chromium alloy; 4. All kinds of stone can be broken to make sand when the pressure is less than 250 MPa; 5. The mobile crusher can be powered by either power supply or diesel engine or diesel generator set; 6. If screening is needed, the crushing and sand making machines with different capacities can match the screening machines with different specifications. |

|||||

1. Wear resistance and long service life

2. Mobile convenient and efficient

3. Closed crushing is more environmentally friendly

4. Stable operation and less time consuming

5. Independent crushing is more reliable

6. Simple structure and easy maintenance

Details are Perfect |

Fighter in Crusher |

|

|

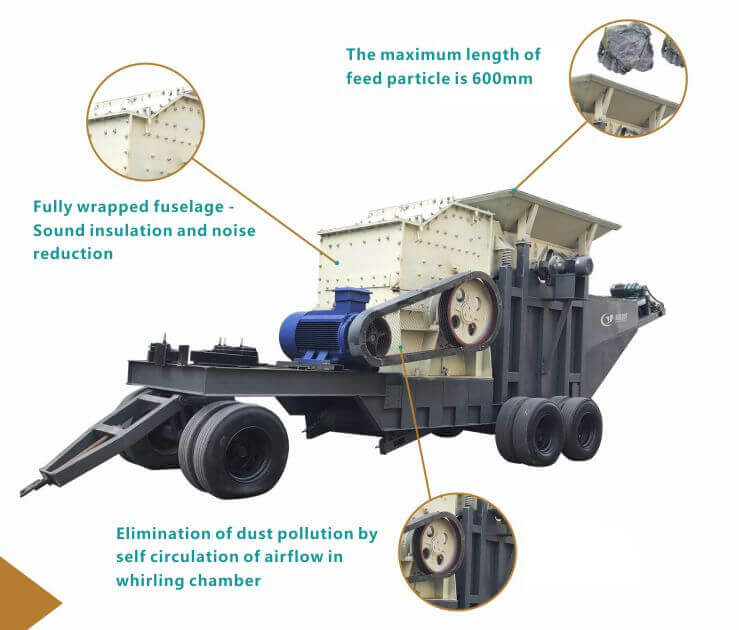

1. Air flow self circulation vortex chamber, dust removal equipment and noise eliminator are added to eliminate dust pollution with high efficiency and environmental protection. 2. The spindle is made of 40grmn alloy, the hammer head is made of mn53 alloy, and the screen and liner are made of mn13gr2 alloy. The service life is much better than that of similar products. 3. The covered fuselage can effectively reduce the production noise, and the fuselage is more solid. Most industries are made of single working components, and the working noise is large. |

Excellent Material Precision Manufacturing New Design Efficient Crushing |

| JXSC Manufacture VS Common VSI Sand Making Machine | ||

| JXSC Manufacture | Common VSI Crusher | |

| Equipment Quality | The core material is mn53, 40grmn, 50gr vanadium and Q345 steel plates with good wear resistance. Hardness, strength industry leading. | Ordinary manganese steel plate is used, with average hardness and strength. |

| Appearance Design | Wrapped shape, one-time molding process, solid and durable, sound insulation and noise reduction. | Most of the industries are made up of single working components, which makes a lot of noise. |

| Production Process | Adopting numerical control automatic production equipment and plasma hydrogen arc welding process, the product has high precision and stronger fuselage. | Most of them are manual welding operation, with high precision and large error. |

| Production Capacity | All products are mechanized and flow process, can be mass produced, master the core technology, and can accept personalized customization. | Small workshop production. It is difficult to achieve large-scale production, mass production, product quality assurance. |

Match Freely and Customize on Demand

Ask Our Technician or Salers For Mobile Crusher Solutions/Price