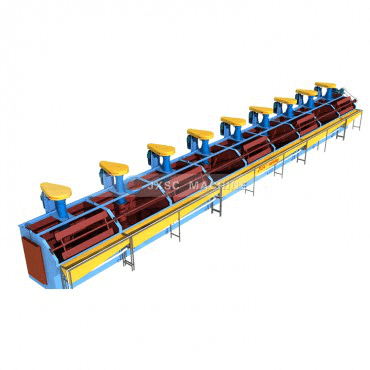

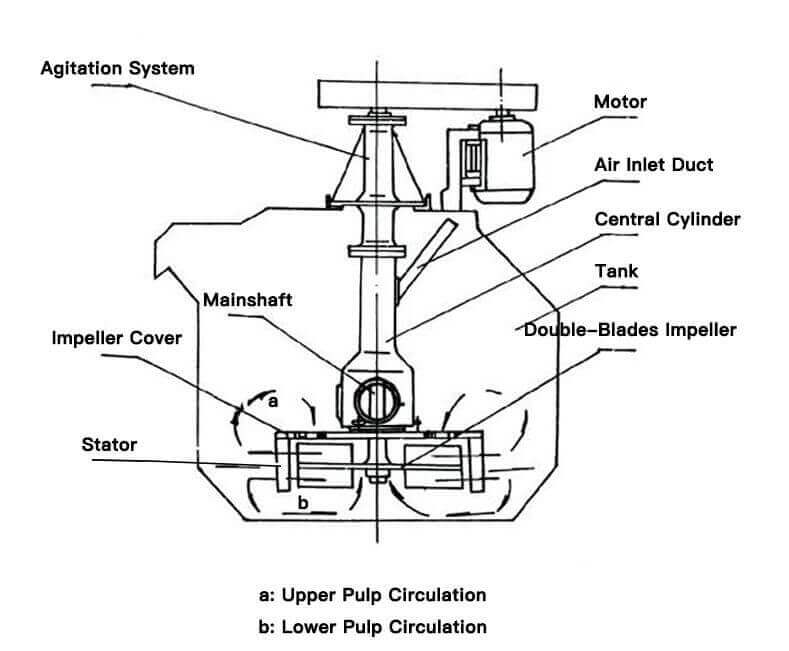

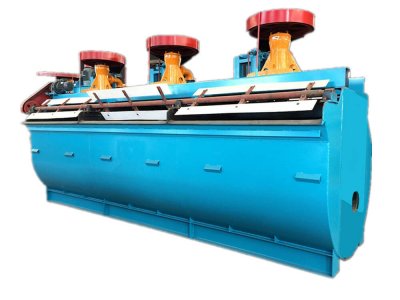

Flotation machines constitute the basic equipment for useful minerals recovery from non-ferrous ores and other raw materials by flotation. They can operate also as individual flotation cells.

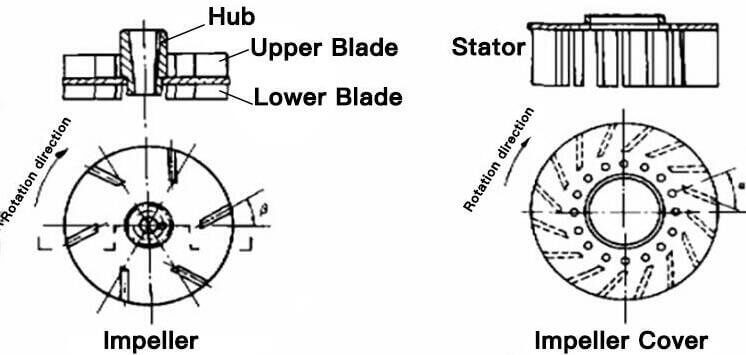

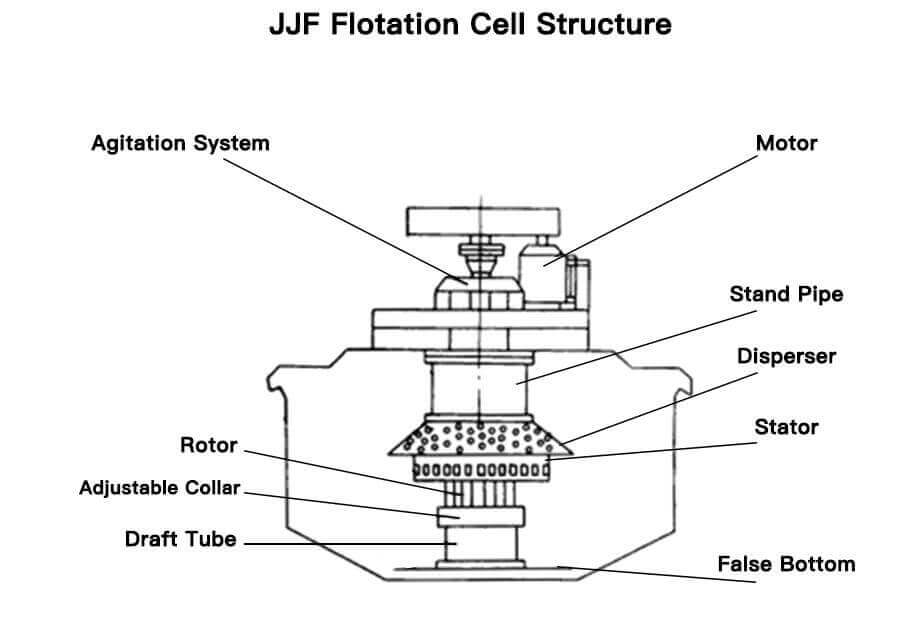

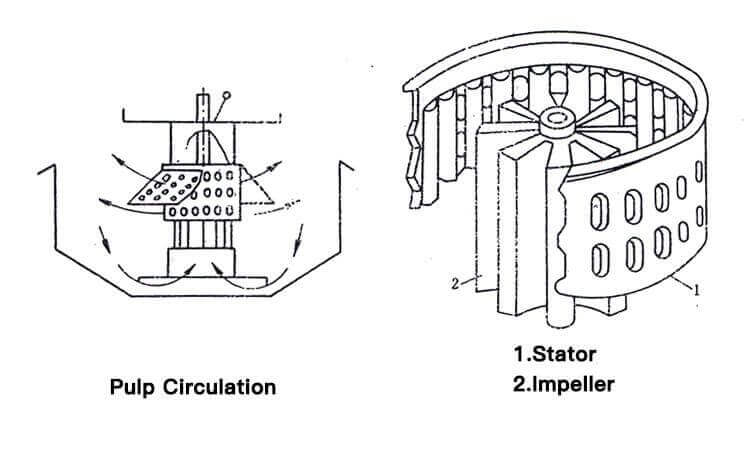

Flotation Cells (Froth Flotation) were developed to separate and recover high-value Sulphide ores from low-grade ore bodies. The Flotation Cell is aerated to produce bubbles and agitated to keep the solids particles in suspension in the pulp. A flotation cell is an appliance in which froth flotation of ores is performed. It has provision for receiving conditioned pulp, aerating this pulp, and for separate discharge of the resulting mineralized froth and impoverished tailings.